Machining guidelines Chapter 2

- Aug 29, 2017

- 3 min read

Parameters for the individual machining processes

2.1 Sawing Plastics can be sawn with a band saw or a circular saw. The choice depends on the shape of the semi-finished product. The use of a band saw is particularly recommended when a “support groove” (prism) is used to cut rods and tubes and also has the advantage that the heat is dissipated via the long saw blade. However, the teeth of the blade must be set adequately so that the blade cannot jam. Circular saws, on the other hand, are mainly used for cutting sheets and blocks with straight edges. Here, attention should be paid that the feed rate is adequate so that chips are removed, that the saw blade does not jam and that the plastic does not overheat at the point where it is being cut. Table 1 contains guiding values for the cutting geometry of the saw blades.

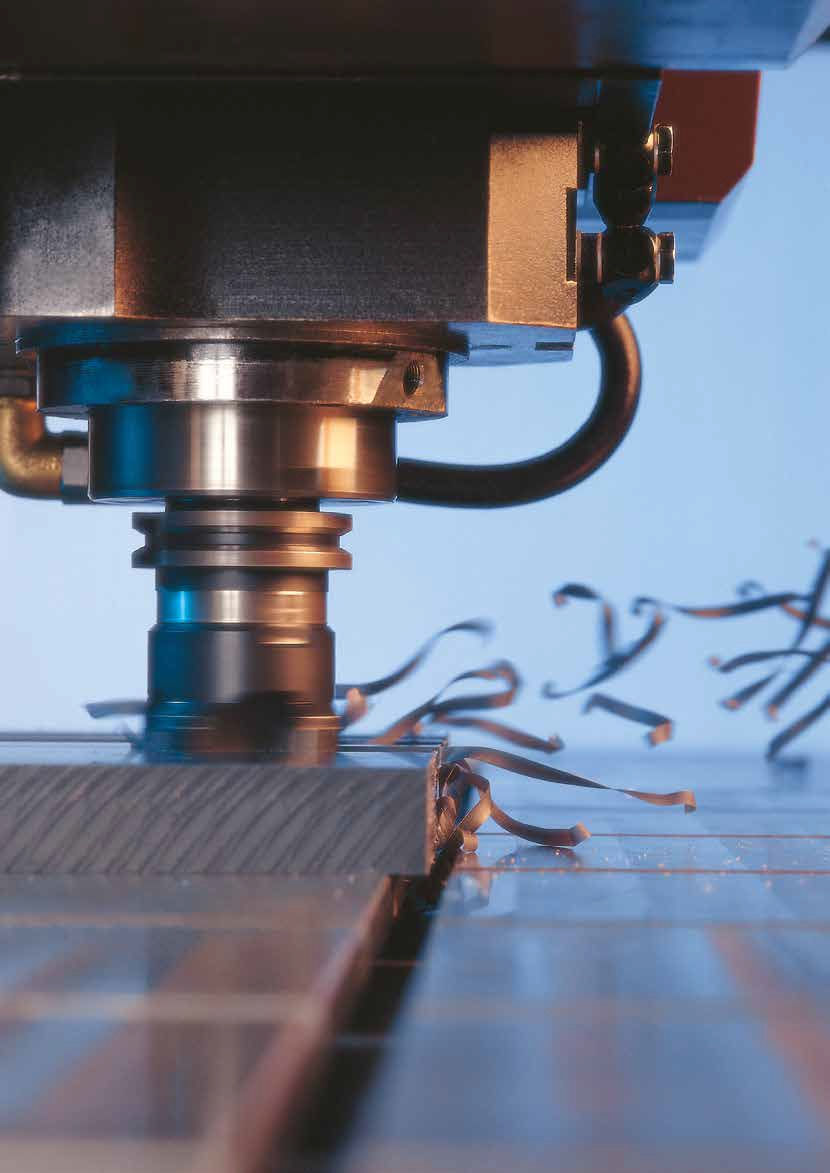

2.2 Milling Milling on conventional machining centres is unproblematic. With a high cutting speed and medium feed rate it is possible to achieve high levels of machining performance with good surface quality and accuracy. Care must be taken that tools with sufficiently large chip space are used. It guarantees a reliable chip removal and it avoids heat congestion. We recommend the values given in the Table in regard to the cutter geometry.

2.3 Turning on a lathe Since most plastics produce unbroken chips, it is important to ensure that the chips are removed, as they would otherwise catch and revolve with the part being turned on the lathe. In addition, because of the low degree of stiffness of plastics, there is a great danger of longer parts sagging, and it is thus advisable to use a steady rest. The values given in the Table apply to the cutter geometry.

2.4 Drilling Drill holes can be made with a conventional HSS drill. If deep holes are being drilled, it must be ensured that the chips are removed, as otherwise the plastic on the walls of the hole will heat to the point of melting and the drill will “clog”. This especially applies to deep holes. For drilled holes in thin-walled workpieces, it is advisable to choose a high drilling speed and, if applicable, a neutral (0°) effective cutting angle. This prevents the drill from sticking in the workpiece and hinders the associated stripping of the hole or the workpiece being drawn up by the drill. The recommended values for drill cutting geometry are shown in the table.

2.5 Drilling large diameters in sections of round rod When drilling, high temperatures build up on the cutting edges, especially with highly crystalline materials such as Nylon, which cannot be adequately dissipated because of the good insulation properties of the plastics. The heat causes an internal expansion in the material, which in turn causes compressive stress in the inside of the rod section. This stress can be so high that the rod tears and splits. This can be avoided to a great extent if the material is machined correctly.

It is advisable to pre-drill the hole and complete it with a right side tool. The pre-drilled holes should not exceed 35 mm in diameter. Drilled holes in long sections of rod must only be made from one side, as otherwise an unfavourable stress relationship is created when the drilled holes meet in the middle of the rod, which can lead to the rod section cracking.

In extreme cases it may be necessary to heat the blank to approx. 120-50 °C and pre-drill it in this condition. The hole can then be completed when the rod has cooled down and when an even temperature has set in throughout the blank. Finishing can take place after complete cooling and achieving a uniform temperature level inside the blank.

2.6 Notes on reinforced and filled plastics Plastics that are reinforced or filled with glass fibres, carbon fibres, glass beads, mineral substances or other substances have a higher level of residual stress compared to non-reinforced or unfilled plastics. The reinforcement and filler materials also make the products harder and more brittle and reduce impact strength. This makes these products susceptible to cracking. During machining the residual stresses may be relieved, which makes itself noticeable by strong deformation, cracking or full failure. The following notes should therefore be taken into account when machining and manufacturing:

If possible the semi-finished products should be heated to approximately 120 °C before drilling or sawing. (Suggested exposure time: approx. 5-6 min per mm of cross-section).

As a minimum a carbide-tipped, but preferably diamond-coated tools should be used for machining.

When clamping and fixing ensure freedom from deformation and expose the material to the minimum possible bending, tensile or compressive forces.

If the above guidelines are observed the production of complex products from engineering plastics using machining processes can be easily achieved even where the highest quality standards of accuracy and functionality are required.

Comments